Principle

The machine is fully enclosed in color, with all components made of stainless steel and equipped with a three-pole purification device. The filtered air meets the requirement of 100000 levels. The simplified and top parts are equipped with a cold wall device to ensure a wall temperature of<80 degrees Celsius. The drying tower is equipped with an air brush scanning device. After being dried by this machine, the traditional Chinese medicine extract powder will not undergo coking and deterioration, greatly reducing the powder collection rate (up to 95% or more), and will not produce mixing or wall sticking phenomena.

Basic principle: The high-speed centrifugal spray device for Chinese herbal extracts is the application of centrifugal spray drying technology in the drying of specific materials. It is also a drying device that uses high-speed centrifugal atomizer to disperse materials into mist, fully contact with hot air, complete instant drying, and form powder finished products.

The spray dryer for Chinese herbal extracts is a spray dryer specially used to solve the problems of Chinese herbal extracts and plant extracts. It solves the following problems in the drying of traditional Chinese medicine extracts in the original LPG high-speed spray dryer:

1. The material adheres to the wall and has low powder collection rate;

2. The material remains stagnant on the wall for a long time, resulting in coking and deterioration of the material;

3. Difficult to clean and does not meet GMP requirements;

4. Low main volume: LPG - 150 spray dryer can only handle 50-60kg/h liquid feed.

Given the above situation, our factory has designed a dedicated drying machine for traditional Chinese medicine extracts based on the material properties and process requirements. It has solved the problem of traditional Chinese medicine extract dryer in history. The dried material has good color and does not deteriorate, greatly improving the economic benefits of the factory. Compared with LPG high-speed centrifugal spray dryer, traditional Chinese medicine extract has the following requirements:

1. Three levels of air purification were adopted to meet the requirement of 300000 levels of intake air;

2. Adopting a cold wall device, the inner wall temperature is lower than 80 ℃, and the material stays on the wall without coking;

3. The efficiency is 3.5 times of the original LPG standard centrifugal spray;

4. Adopting a quick opening flushing device, suitable for various production requirements;

5. Wet dust removal is adopted to prevent dust from coming out, which meets environmental requirements;

6. Adopting an air sweeping device, the material stays on the wall for a short time and does not stick to the wall;

7. The atomizer adopts frequency conversion adjustment;

8. Adopting PLC control and program control system screen display;

9. With cleaning device;

10. Dry air is used to transport and receive materials in a closed manner.

Characteristic

★ The tower body has a cold air jacket;

★ The tower body is equipped with an automatic rapping device;

★ The tower body and pipeline are equipped with quick opening cleaning holes and sewage holes;

★ Automatic control of constant temperature feeding tank;

★ Manual high-pressure washing tower with accessories;

★ The part in contact with the material is made of stainless steel material (or all stainless steel)

★ The material collection adopts a two-stage cyclone dust collector, or a one-stage cyclone dust collector and a wet dust collector;

★ Automatic control and continuous device for inlet air temperature;

★ Equipped with an air scanning device.

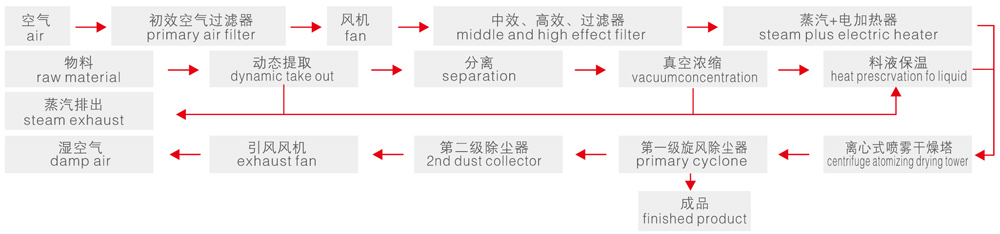

Technological process

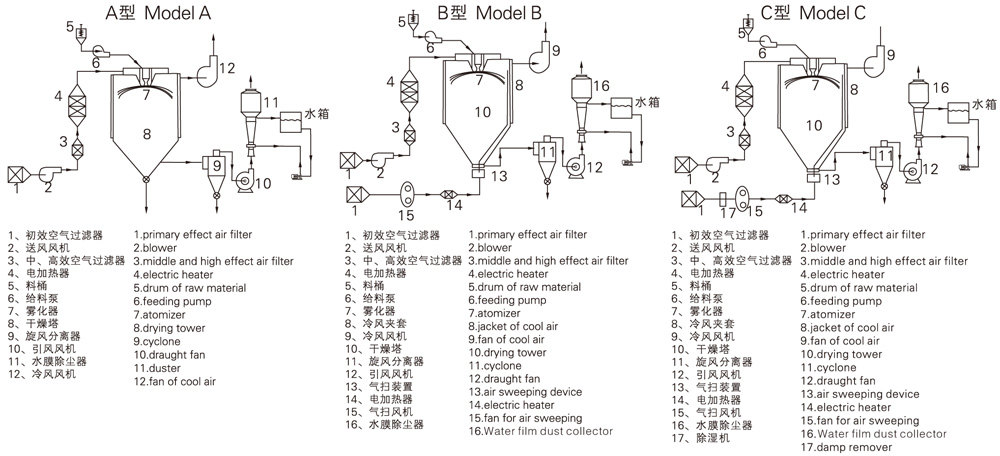

Installation reference diagram

Model | ZPG-5 | ZPG-10 | ZPG-25 | ZPG-50 | ZPG-80 | ZPG-100 | ZPG-150 | ZPG-200 | ZPG-300 | |

Moisture evaporation (kg/h) | 5 | 10 | 25 | 50 | 80 | 100 | 150 | 20 | 300 | |

Material liquid processing capacity (kg/h) | 6-7 | 12-14 | 25-34 | 50-68 | 80-108 | 100-135 | 150-203 | 200-270 | 300-406 | |

Finished product content(kg/h) | 1-2 | 2-4 | 4.8-7.2 | 9.2-14 | 14.8-22.4 | 18.4-28 | 24-42 | 36.8-56.4 | 55-85 | |

Solid content of wet materials(%) | 18-25 | |||||||||

Finished product moisture content (%) | 3-5 | |||||||||

Electric power (kw) | 36 | 45 | 63 | 99 | 132 | 153 | 204 | 246 | 330 | |

Heat source | Steam power on | |||||||||

Product capture methods and efficiency | Two stage cyclone dust collector or one stage cyclone dust collector and one stage wet dust collector ≥ 95% | |||||||||

Automatic control instrument | Hot air temperature and exhaust temperature indicators, automatic adjustment of temperature controller | |||||||||

Inlet air temperature (℃) | 150-200 | |||||||||

Air outlet temperature (℃) | 80-100 | |||||||||

Overall dimensions(mm) | Long L | 5000 | 5500 | 7000 | 8000 | 9800 | 11000 | 12200 | 14100 | 15000 |

Wide W | 3000 | 3500 | 4000 | 5000 | 5700 | 6200 | 7000 | 7800 | 9000 | |

High H | 4500 | 4600 | 5200 | 6500 | 7600 | 8100 | 9000 | 9850 | 11100 | |

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.